usp compressed air system testing|7356 : export Each of the types of potential air quality issues has different underlying causes and testing methods. In general, compressed air testing is governed by ISO 8573. Depending on the application, additional standards .

July 1, 2022 ·. My favorite sous chef! Sophie has washed the mint, scrubbed the fresh lemons from California, and is prepping for drink and dessert garnishes for tomorrow. We .. See more. 1. Casual Jane. 3 likes. site.

{plog:ftitle_list}

Resultado da Elephant Bet is operated by MOTA, TAVARES & BARROS SA - NIF 5417259144 - Licence N° B20081200360166654683/ISJ/MF/20

The USP (the US Pharmacopoeia) handle the testing of water or oil content quite easily: the so-called mirror test is required. In this case, one lets the gas flow against a clean .INTRODUCTION. 16 This guidance is intended to assist manufacturers of medical gases in complying with applicable. 17 current good manufacturing practice (CGMP) regulations (21 .Parameters that are evaluated include filter integrity, air velocity, air patterns, air changes, and pressure differentials. These parameters can affect the microbiological bioburden of the clean .The validation of a Compressed Air System in the pharmaceutical industry is typically performed according to the requirements and guidelines provided by regulatory authorities such as the International Society for Pharmaceutical .

ASUs separate atmospheric air into its constituent gases of oxygen, nitrogen, and argon through a process of pre-cleaning, compression, cooling, and fractional distillation of liquefied air. Each of the types of potential air quality issues has different underlying causes and testing methods. In general, compressed air testing is governed by ISO 8573. Depending on the application, additional standards .

An example of a method for conducting a particulate challenge test to the system by increasing the ambient particle concentration in the vicinity of critical work areas and equipment has been developed by Ljungquist and Reinmuller. 1 First, smoke generation allows the air movements to be visualized throughout a clean room or a controlled .

Regular testing of compressed air systems and other process gases that come into contact with pharmaceutical products is critical to ensuring the quality and integrity of the product. . Based on the generation technology and/or USP/EU .45 in the United States Pharmacopeia-National Formulary (USP-NF). Gases that do not meet the 46 definition of a drug, including gases intended for industrial applications or nondrug medicalMicrobial Testing of Compressed Air Micro Testing of Compressed Air or Bioburden Testing per ISO 8573-7 is generally conducted by the pharmaceutical, medical device and food industries. Microbial contaminants found in the compressor or compressed air lines can be devastating to a final product in these industries. A regular Micro Testing program can provide insight to a . 3.1 Sterilise the air sampling flask together with 100 ml SCDM, silicone tube for inlet & outlet. 3.2 Take the assembly to the sampling area and sanitize the sampling site with 70% IPA. 3.3 Open valve of the compressed air system for five minutes and allow air to pass out.

In the absence of specified standards governing compressed air quality testing in the pharmaceutical manufacturing process, it is often best to use site-specific air and pure gas testing programs for Points of Use (POU). . Indirect Product Contact, United States Pharmacopeia (USP), European Pharmacopoeia, ISO 8573, ISO 14664 compressed air . Pure gas testing can help users meet standards like JECFA, FCC, CGA, EU 231, NFPA 99, USP, ISO 8573 and more. Whether you’re testing nitrogen, oxygen, argon, or mixed gases, Trace Analytics has the expertise and experience to make the whole process simple and straightforward. . Trace Analytics, LLC, is an ISO 17025-accredited laboratory .Compressed air or breathing air ISO 8573 EN 12021 Table 1: Compressed air or breathing air Quality and proximity Compliant with all the international and local pharmacopoeias, our analyses are done in specially equipped laboratories, however some tests can be conducted onsite, using mobile analysis systems, enabling quick access to results. SGS . oil free compressed air – standards do not set reasonable mg/m 3 limits. In most cases, compressed air contacts the product. As the pharmaceutical industry has grown, so too has the use of compressed air for breathing air, equipment, and instrument air operation. The USA accounts for about half of the global pharmaceutical market.

Thorough, documented training is critical when it comes to making sure personnel are adequately prepared to sample microbiological organisms from any facility system. Compressed air systems are unique; ISO and USP have select protocols specifically designed for the analysis of microbial contaminants, which utilize negative controls, blinds, and .

The United States accounts for roughly half of the global pharmaceutical market. This certainly keeps the Food and Drug Administration (FDA) busy in its oversight of pharmaceutical safety and effectiveness, including with the production processes. As the pharmaceutical industry has grown, so too has its utilization of compressed air for breathing . Compressed air systems are a critical component of many pharmaceutical manufacturing facilities. With any new system creation, addition, or change, a validation should be performed to ensure the compressed air is of appropriate quality for its intended use. . USP, ISPE, or CGA). Particles can be analyzed in a variety of ways. Some .Assay— Determine the oxygen concentration of Medical Air using an electrochemical cell analyzer readable to 0.1% of oxygen and calibrated with ambient air to an accuracy of ± 0.2% of oxygen. [NOTE— The instrument utilizes the variations of electric current produced by the interaction of oxygen with an electrochemical cell to display the oxygen strength of a confined .With an air sampler, water vapor could affect viable particles and their ability to grow in the gas line. Testing for Non-Viable Particles Using a Particle Counter When testing a compressed gas line using a particle counter, ISO 8573-4 should be followed. The particle counter

In the 2010 edition of ISO 8573-1, the particle size and maximum number of particles were harmonized with current filter manufacturer’s capabilities. This harmonization created an effective method to communicate .Why compressed air testing is required? . counting is performed by connecting a Laser Particle Counter with High Pressure Diffuser to an access point on the compressed air system, with instantaneous differential counts being measured for each of the specified ranges of particle size . Following test to be performed as per BP and USP:-Sr. no . In most cases, end users select compressed air system components by comparing technical data from various air treatment manufactures. In 1991, the International Standards Organization (ISO) established the 8573 compressed air quality standard to facilitate compressed air system component selection, design and measurement.Compressed Air System for Packaging Area The area has ten (10) filtered (process air) product contact and non-product contact compressed air point of use (POU) described in Table 2 and one (1) non-filtered (instrument air) non-product contact compressed air point of use (POU) described in Table 3.

ambient air and get into the compressed air system through the compressor intake air. The reason for the contamination can be a major road or construction site nearby, for example. The risk of humidity occurring in the compressed gas system increases with air humidity in the ambient air. The contamination presents risks: on the one hand, itAn isolator used for sterility testing is equipped with microbial retentive filters (HEPA filters are required). At rest, the isolator meets the particulate air-quality requirements for Class 100 area as defined in U.S. Federal Standard 209E (see Microbiological Evaluation of Clean Rooms and Other Controlled Environments 1116).However, the isolator need not meet Class 100 conditions .

At CEGTH, we offer effective testing solutions for your compressed air systems as per the guidelines of ISO: 8573/ USP/EP/BP. Breathing Air Validation. The Compressed Gas Association sets quality standards for breathing air is GRADE D (ANSI/CGA G-7.1’97) CEGTH offers testing of breathing air quality for the following parameters:

Common uses of compressed air The ISPE Good Practice Guide asserts that a logical method for determining the requirements of a facility’s compressed air quality is to review the role of the gas in the process. Process gases and compressed air are used in a variety of ways depending on the product manufactured. While some facilities use compressed air in .

6.0 SYSTEM DESCRIPTION: Air compressor unit has an air unit system which is responsible for delivering quality compressed air at the outlet. It starts from the suction filter of the compressor and ends at the final service valve of the unit. Air compressor provides a filter of superior grade at the suction of the compressor to avoid any

5.7 Frequency of testing: (1) Once per quarter for compressed air and nitrogen gas.- In Parenteral Dept. (2) Once per quarter for Compressed air – In Solid Dosage Area. 5.8 Sample quantity: Adjust the flow meter to 6 m3/hr & draw the sample for 10 min to sampled 1 m3 of air or nitrogen gas.21 CFR 211.46(c) states, in part, that “Air filtration systems, including prefilters and particulate matter air filters, shall be used when appropriate on air supplies to production areas * * *.”

Since compressed air is a critical factor in the manufacturing of medical devices, this applies to compressed air systems as well. Contaminated compressed air can compromise the integrity of the medical device products and put consumers at risk. Compressed air must meet medical device quality standards and manufacturers have to provide .

Drop Dart Impact Tester discount store

Validation of Compressed Air Systems

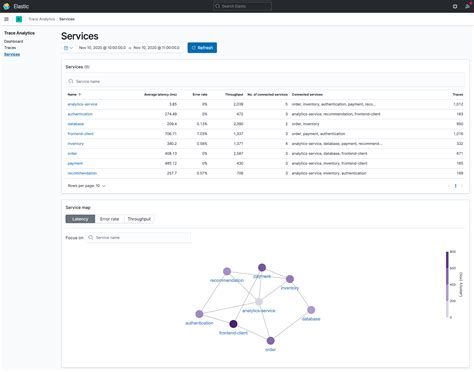

Trace Analytics

Watch Private Sex Tapes! See this video on demand and other sex videos only at FreeOnes!

usp compressed air system testing|7356